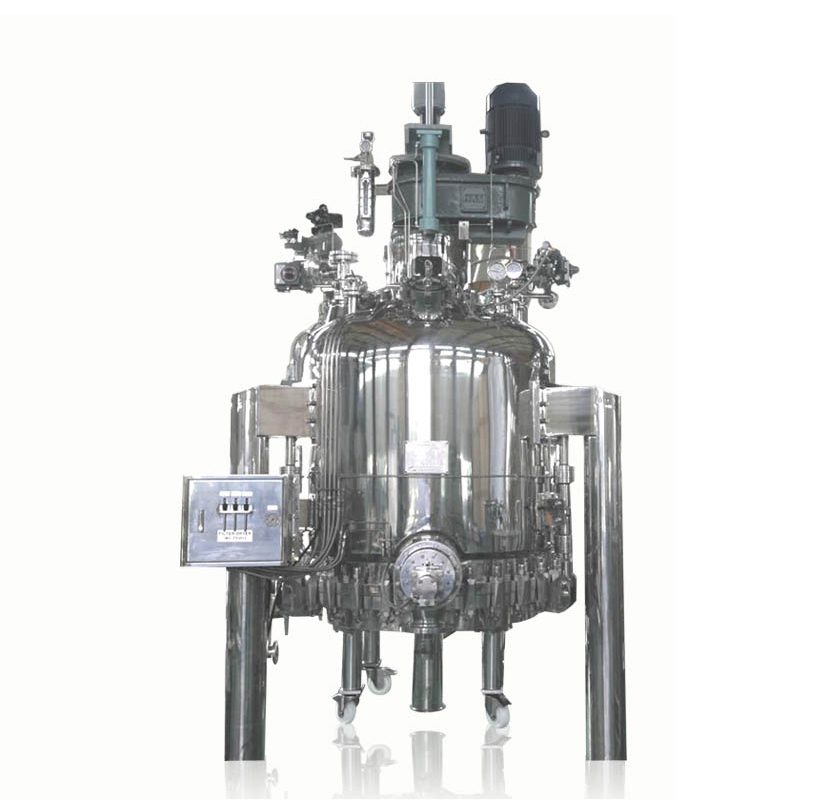

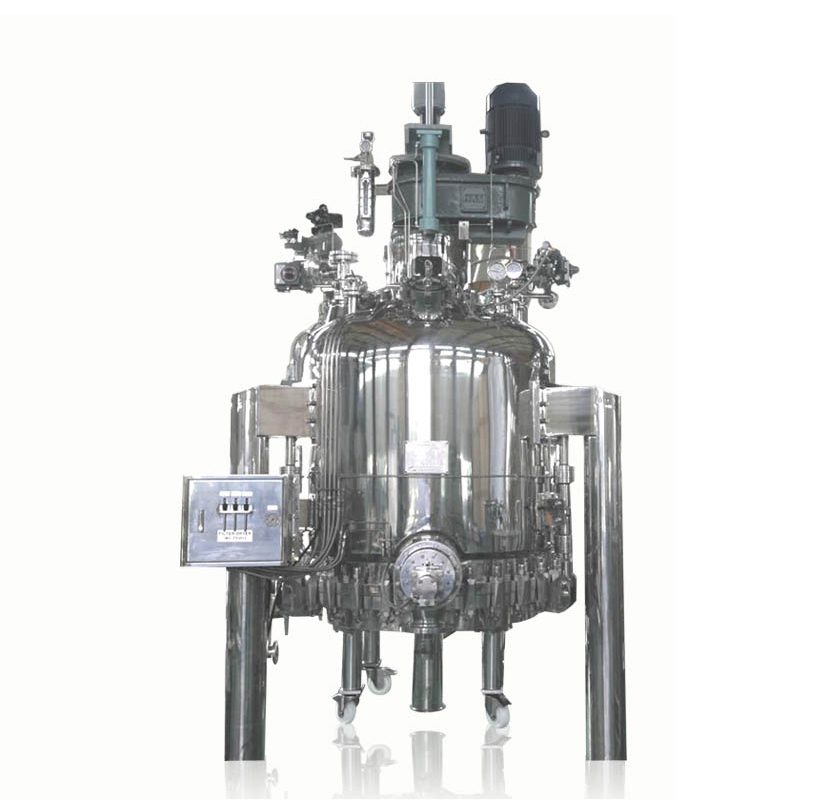

Filter Dryer (Static Type)

The Filter Dryer can perform simultaneously two processes of filtration and cake drying without transferring product to the other equipment.

It consists of a heated agitator, bottom, and body and it uses vacuum and pressure during the filtration process.

Optional specifications include dust filters, vacuum pumps and solvent recovery systems, suitable for process of handling sensitive products or for drying very low residual humidity products.

Features

- Entirely contamination-free single process unit by non-transfer products

- Full automatic operation of mixing, filtering, drying, washing, and extraction

- Protecting the worker & sterile environment by the Close System

Application

- Pharmaceutical

- Chemical

- Fine Chemicals

- Semi Conduct, and Etc.

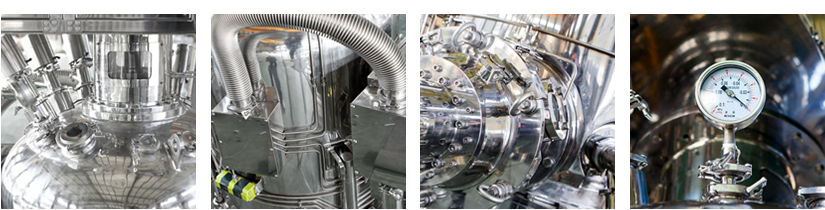

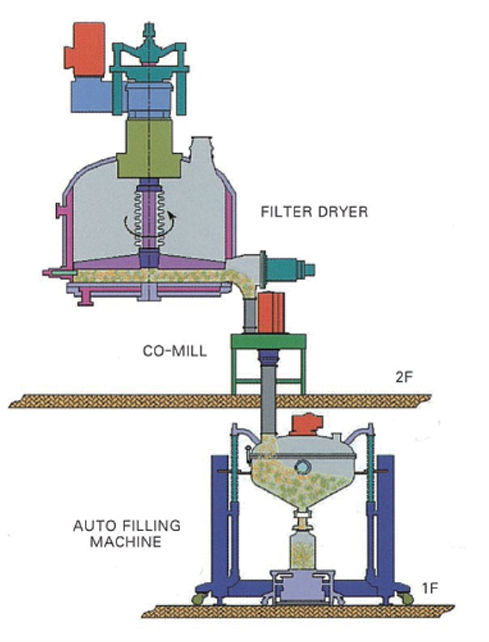

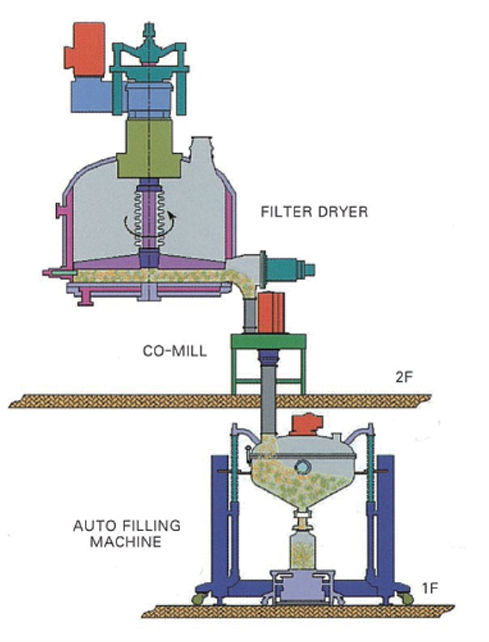

Auto Filling Machine

Process Flow : Filter Dryer, Co-Mill, Auto Filling Machine

Filter Dryer, Co-Mill and Auto Filling Machine can be used as a single process unit to prevent any contaminants that may arise from the product transportations.

Features

- Application of Mechanical Seal with High Efficiency for Aseptic/Sterilization Facilities

- CIP/SIP function

- Easy to assemble and clean

- Record temperature & pressure and print

Application

- Aseptic/Sterile Pharmaceutical facilities

360VR

Move the arrow left and right to return the product image to the left and right.

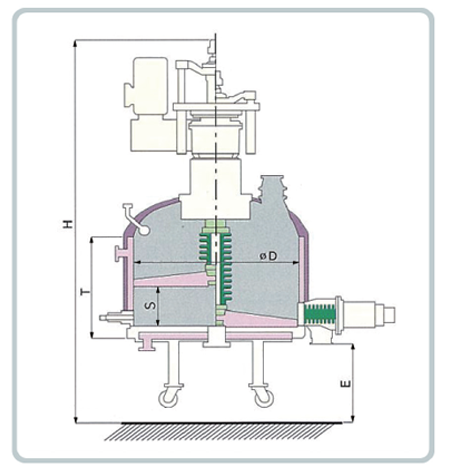

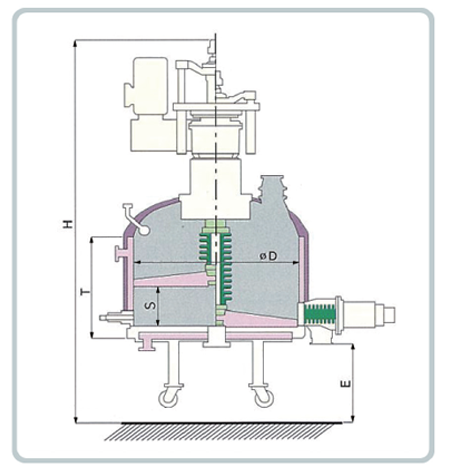

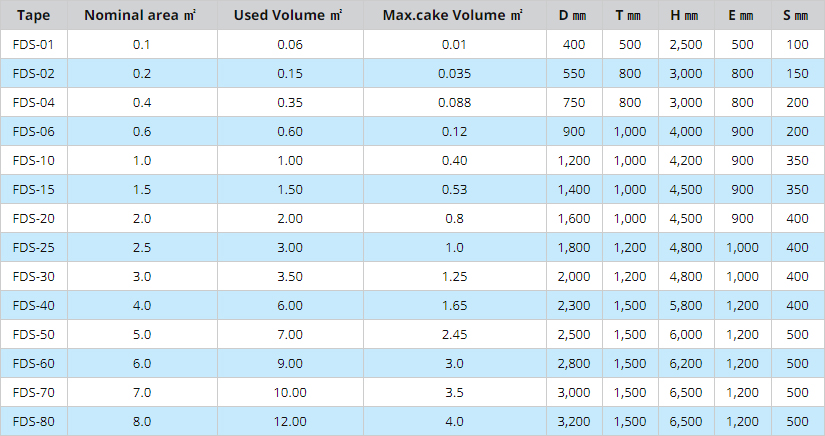

Construction

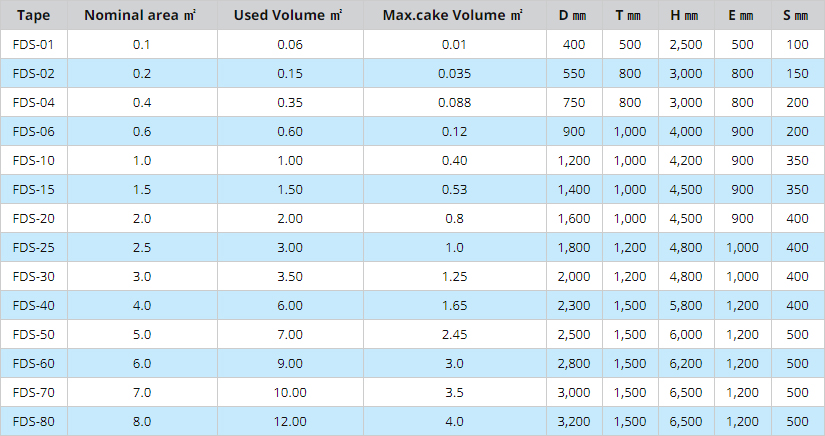

| Tape |

Nominal area ㎡ |

Used Volume ㎡ |

Max.cake Volume ㎡ |

D ㎜ |

T ㎜ |

H ㎜ |

E ㎜ |

S ㎜ |

| FDS-01 |

0.1 |

0.06 |

0.01 |

400 |

500 |

2,500 |

500 |

100 |

| FDS-02 |

0.2 |

0.15 |

0.035 |

550 |

800 |

3,000 |

800 |

150 |

| FDS-04 |

0.4 |

0.35 |

0.088 |

750 |

800 |

3,000 |

800 |

200 |

| FDS-06 |

0.6 |

0.60 |

0.12 |

900 |

1,000 |

4,000 |

900 |

200 |

| FDS-10 |

1.0 |

1.00 |

0.40 |

1,200 |

1,000 |

4,200 |

900 |

350 |

| FDS-15 |

1.5 |

1.50 |

0.53 |

1,400 |

1,000 |

4,500 |

900 |

350 |

| FDS-20 |

2.0 |

2.00 |

0.8 |

1,600 |

1,000 |

4,500 |

900 |

400 |

| FDS-25 |

2.5 |

3.00 |

1.0 |

1,800 |

1,200 |

4,800 |

1,000 |

400 |

| FDS-30 |

3.0 |

3.50 |

1.25 |

2,000 |

1,200 |

4,800 |

1,000 |

400 |

| FDS-40 |

4.0 |

6.00 |

1.65 |

2,300 |

1,500 |

5,800 |

1,200 |

400 |

| FDS-50 |

5.0 |

7.00 |

2.45 |

2,500 |

1,500 |

6,000 |

1,200 |

500 |

| FDS-60 |

6.0 |

9.00 |

3.0 |

2,800 |

1,500 |

6,200 |

1,200 |

500 |

| FDS-70 |

7.0 |

10.00 |

3.5 |

3,000 |

1,500 |

6,500 |

1,200 |

500 |

| FDS-80 |

8.0 |

12.00 |

4.0 |

3,200 |

1,500 |

6,500 |

1,200 |

500 |

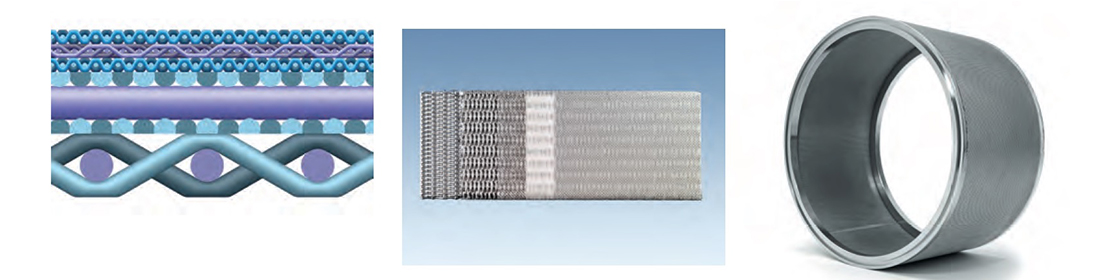

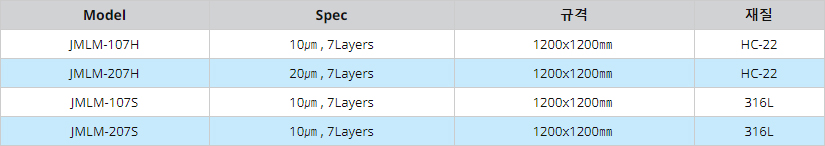

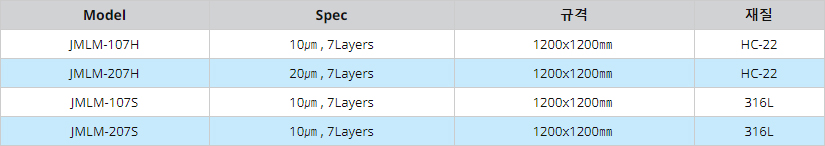

| Model |

Spec |

standard |

material |

| JMLM-107H |

10㎛ , 7Layers |

1200x1200㎜ |

HC-22 |

| JMLM-207H |

20㎛ , 7Layers |

1200x1200㎜ |

HC-22 |

| JMLM-107S |

10㎛ , 7Layers |

1200x1200㎜ |

316L |

| JMLM-207S |

10㎛ , 7Layers |

1200x1200㎜ |

316L |

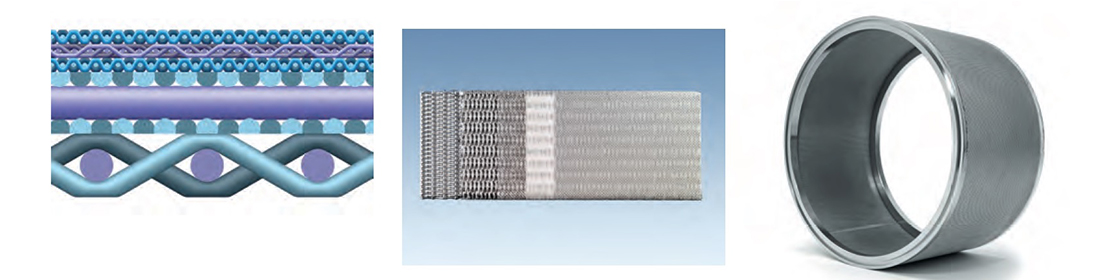

Filter Multi Mesh is a sintered component and its application is widely used for viscous liquid separation (filtration).

KOREA

KOREA